Understanding Different Types of Pipes and Couplers for Better Performance

When it comes to constructing and maintaining efficient systems, whether for plumbing, industrial applications, or infrastructure projects, the choice of pipes and couplers is crucial. The performance, durability, and cost-effectiveness of your system can be significantly impacted by the types of pipes and couplers you choose. This guide provides an in-depth look at different types of pipes and couplers and how to select the right ones for optimal performance.

1. Types of Pipes

a. PVC Pipes

Polyvinyl Chloride (PVC) pipes are among the most commonly used pipes in residential and commercial applications. They are known for their affordability, lightweight nature, and resistance to corrosion.

- Advantages:

- Resistant to chemicals and corrosion.

- Lightweight and easy to handle.

- Low cost and easy to install.

- Disadvantages:

- Can be brittle in cold temperatures.

- Not suitable for high-pressure applications.

Applications: Ideal for drainage, irrigation, and low-pressure water systems.

b. CPVC Pipes

Chlorinated Polyvinyl Chloride (CPVC) pipes are similar to PVC but with added chlorine, which makes them suitable for hot water applications.

- Advantages:

- Can handle higher temperatures than PVC.

- Resistant to corrosion and chemical damage.

- Disadvantages:

- More expensive than PVC.

- Can become brittle over time.

Applications: Used in hot water systems, industrial applications, and chemical processing.

c. PEX Pipes

Cross-Linked Polyethylene (PEX) pipes are flexible and can be easily installed in tight spaces. They are resistant to scale and chlorine and do not corrode or develop pinholes.

- Advantages:

- Flexibility allows for fewer fittings and easier installation.

- Resistant to freezing and thawing.

- Disadvantages:

- Can be more expensive than PVC and CPVC.

- Susceptible to UV damage if exposed.

Applications: Suitable for residential water supply systems and radiant heating.

d. Copper Pipes

Copper pipes are durable and resistant to corrosion. They are often used in plumbing for both water supply and refrigeration systems.

- Advantages:

- Long-lasting and reliable.

- High thermal conductivity.

- Disadvantages:

- More expensive than plastic pipes.

- Requires special tools for cutting and fitting.

Applications: Ideal for potable water systems and air conditioning systems.

e. Steel Pipes

Steel pipes come in various grades and are used for high-pressure applications. They are known for their strength and durability.

- Advantages:

- Strong and able to withstand high pressure.

- Suitable for both high and low-temperature applications.

- Disadvantages:

- Prone to rust and corrosion without proper coating.

- Heavier and more challenging to install.

Applications: Common in industrial and heavy-duty applications.

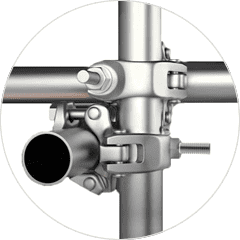

2. Types of Couplers

a. Compression Couplers

Compression couplers are used to connect two pipes together by compressing a ring onto the pipe ends.

- Advantages:

- Easy to install and disassemble.

- Provides a secure, leak-proof connection.

- Disadvantages:

- Can be more expensive than other types of couplers.

- May require periodic tightening.

Applications: Used in plumbing and HVAC systems.

b. Threaded Couplers

Threaded couplers have internal threads that allow them to screw onto the external threads of pipes.

- Advantages:

- Provides a strong, tight connection.

- Easy to install and adjust.

- Disadvantages:

- Can be prone to leaks if not properly sealed.

- Threads can wear out over time.

Applications: Common in water and gas pipelines.

c. Slip Couplers

Slip couplers are designed to fit over the ends of pipes without threading or compression.

- Advantages:

- Simple to use and install.

- Allows for slight adjustments in pipe length.

- Disadvantages:

- Not suitable for high-pressure applications.

- Requires precise alignment for effective use.

Applications: Often used in repairs and adjustments.

d. PVC Couplers

PVC couplers are specifically designed for use with PVC pipes and are often used in plumbing and irrigation systems.

- Advantages:

- Easy to install and fit.

- Affordable and durable.

- Disadvantages:

- Not suitable for high-pressure or high-temperature applications.

Applications: Ideal for PVC pipe systems in various settings.

3. Choosing the Right Pipe and Coupler

Selecting the appropriate pipes and couplers for your project involves considering several factors:

- Application Requirements: Understand the specific needs of your system, including pressure, temperature, and chemical exposure.

- Material Compatibility: Ensure that the materials of the pipes and couplers are compatible with each other and with the substances they will transport.

- Installation Environment: Consider factors such as exposure to weather, potential for physical impact, and ease of access for maintenance.

- Budget: Balance your budget with the performance requirements of the pipes and couplers.

4. Maintenance and Inspection

Regular maintenance and inspection of pipes and couplers can prevent issues such as leaks, corrosion, and blockages. Inspect connections and joints periodically and replace any damaged components promptly to ensure the long-term performance of your system.

Conclusion

Understanding the different types of pipes and couplers and their applications is essential for ensuring the efficiency and durability of your systems. By selecting the right components and maintaining them properly, you can optimize performance and minimize the risk of issues.

For more information and expert advice on pipes and couplers, feel free to reach out to our team at NTURM Engineers Ltd. We are here to help you make informed decisions for all your piping needs.

Leave a Reply