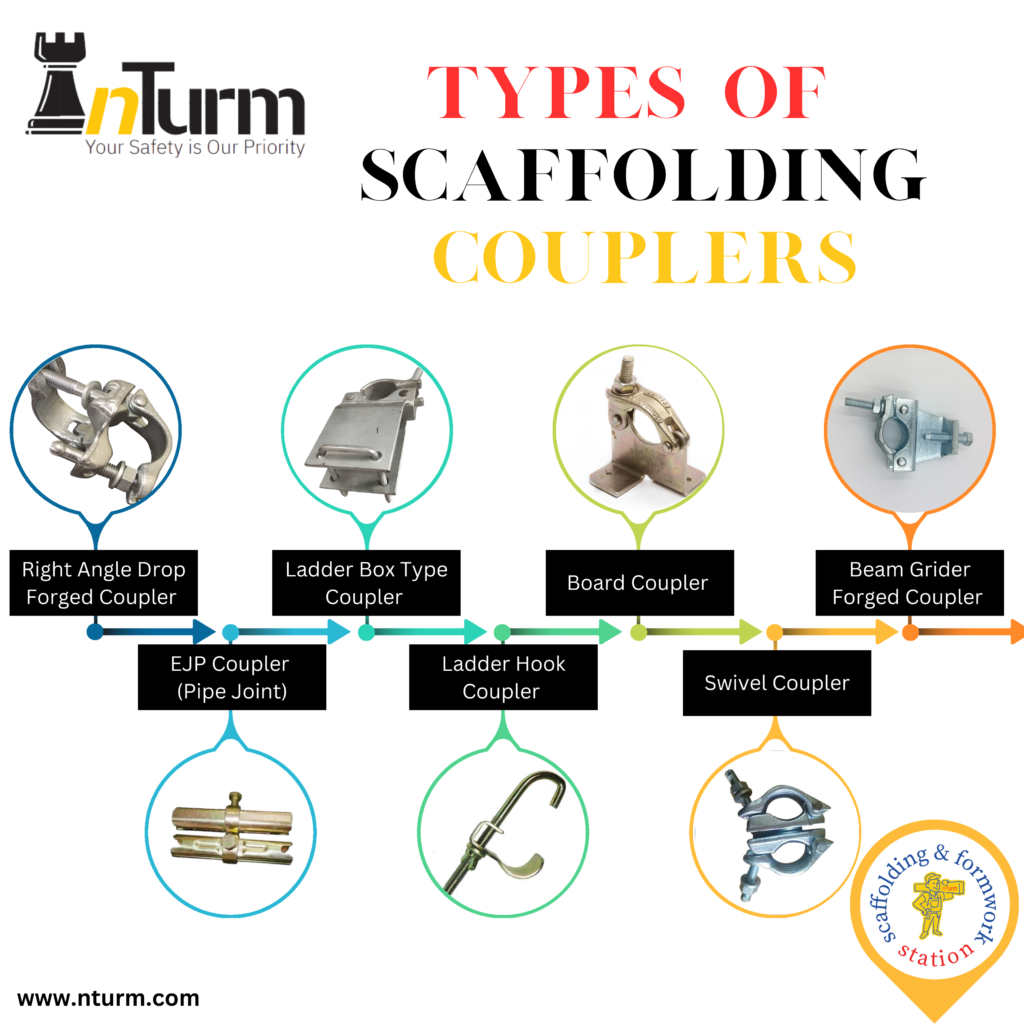

Top 7 Types of Scaffolding Couplers: A Complete Guide

Scaffolding is a vital part of construction and maintenance projects, providing a temporary platform for workers and materials. Among its essential components are scaffolding couplers, which connect and secure scaffold tubes to form a strong, stable structure. Choosing the right type of coupler can significantly affect the safety and efficiency of your scaffolding system.

In this blog, we’ll explore the top 7 types of scaffolding couplers, their uses, and why they matter.

1. Right Angle Drop Forged Coupler

The Right Angle Drop Forged Coupler is one of the most commonly used couplers in scaffolding. It connects two scaffold tubes at a 90-degree angle, ensuring a rigid and stable joint.

- Material: Typically made from drop-forged steel for strength and durability.

- Use: Provides structural stability, ideal for vertical and horizontal tube connections.

- Key Benefit: Its robust design ensures maximum load-bearing capacity.

2. EJP Coupler (End Joint Pin Coupler)

The EJP Coupler, also known as an End Joint Pin Coupler, is designed to join two scaffold tubes end-to-end.

- Material: Lightweight yet strong materials like pressed steel.

- Use: Ideal for extending scaffold tubes in a straight line.

- Key Benefit: Provides a smooth and secure connection without overlapping tubes.

3. Ladder Box Type Coupler

The Ladder Box Coupler is specifically designed for attaching ladders to scaffolding systems.

- Material: Pressed steel or forged steel.

- Use: Ensures ladders are securely fixed to scaffolding, enhancing safety.

- Key Benefit: Its specialized design prevents movement, making it safer for workers to access elevated platforms.

4. Board Retaining Coupler

The Board Retaining Coupler secures scaffold boards in place, preventing them from slipping or moving during use.

- Material: High-quality steel with anti-corrosion finishes.

- Use: Fixes boards to scaffold tubes for safe footing.

- Key Benefit: Improves worker safety by stabilizing walking surfaces.

5. Swivel Coupler

The Swivel Coupler allows for flexible connections between scaffold tubes, enabling them to join at any angle.

- Material: Forged steel or pressed steel.

- Use: Commonly used in complex scaffolding structures requiring angled connections.

- Key Benefit: Provides unmatched versatility and flexibility in scaffolding designs.

6. Beam Girder Forged Coupler

The Beam Girder Coupler is used to secure scaffold tubes to structural beams or girders.

- Material: Heavy-duty forged steel.

- Use: Ideal for industrial or heavy-duty construction projects.

- Key Benefit: Ensures a strong and reliable connection between scaffolding and structural supports.

7. Putlog Coupler

The Putlog Coupler connects scaffold tubes to horizontal members or walls.

- Material: Lightweight steel.

- Use: Common in bricklaying and masonry work where scaffolding supports walls.

- Key Benefit: Simplifies wall support and positioning during construction.

Why Choosing the Right Coupler Matters Scaffolding Couplers

Using the correct scaffolding coupler not only ensures structural stability but also enhances worker safety. Each coupler type has a specific purpose, and understanding their functions can help you design a scaffolding system tailored to your project’s needs.

Final Thoughts

Scaffolding couplers are the unsung heroes of safe and efficient construction. From Right Angle Drop Forged Couplers to Beam Girder Couplers, each type plays a crucial role in creating a reliable scaffolding system. By choosing the right coupler for your project, you can ensure safety, durability, and compliance with industry standards.

Remember, always source your couplers from reputable suppliers and regularly inspect them for wear and tear. Safety comes first in every construction project!

Leave a Reply