H frames are a crucial element in various structural and engineering projects. They provide stability, support, and an organized framework that can be used in construction, design, and other applications. In this guide, we’ll walk you through the process of implementing H frames in your projects, ensuring a thorough understanding and practical application.

1. Understanding H Frames

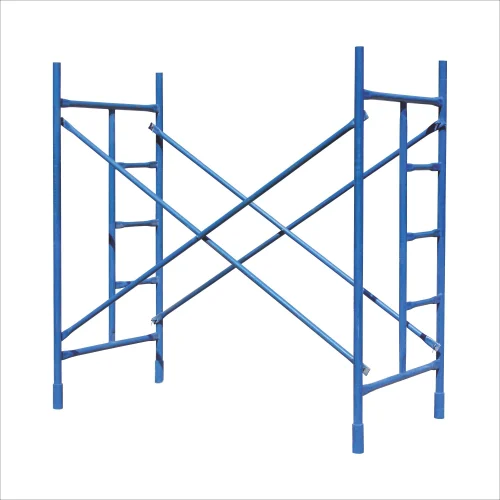

Before diving into implementation, it’s essential to understand what H frames are. An H frame is a structural framework shaped like the letter “H.” It typically consists of two vertical members connected by a horizontal member. This simple design offers great stability and is used in numerous applications, including building construction, scaffolding, and even in the design of mechanical components.

2. Identifying the Need for H Frames

Not every project requires H frames. Determine if an H frame is suitable by considering the following factors:

- Structural Requirements: Assess the load-bearing and stability requirements of your project.

- Design Considerations: Evaluate how an H frame will fit into your overall design.

- Budget and Resources: Consider the cost and availability of materials and tools.

3. Designing Your H Frame

The design phase is crucial to ensure that the H frame will meet the specific needs of your project. Here’s how to approach it:

- Determine Dimensions: Establish the height, width, and thickness of the vertical and horizontal members based on the load requirements and space constraints.

- Material Selection: Choose appropriate materials such as steel, aluminum, or wood. Each material has its advantages depending on the project’s demands.

- Load Analysis: Calculate the expected loads and forces acting on the H frame to ensure it can handle them without compromising safety.

4. Preparing Materials and Tools

Once you have your design, gather the necessary materials and tools:

- Materials: Depending on your design, this might include steel beams, wood planks, bolts, nuts, and welding equipment.

- Tools: Common tools include measuring tapes, saws, drills, welding machines, and safety equipment.

5. Constructing the H Frame

Follow these steps to build your H frame:

- Cut the Materials: Cut the vertical and horizontal members to the required dimensions using appropriate tools.

- Assemble the Frame: Position the vertical members and connect them with the horizontal member. Ensure that the connections are secure.

- For Steel Frames: Use welding to join the components or bolts for a modular approach.

- For Wood Frames: Use screws or nails, and consider reinforcing joints with metal brackets if necessary.

- Check Alignment: Verify that all parts are aligned correctly and that the frame is level.

- Secure Connections: Tighten all bolts or welds to ensure a strong, stable structure.

6. Testing and Verification

Before using the H frame in your project, it’s crucial to test and verify its integrity:

- Load Testing: Apply a test load to ensure the frame can handle the expected stresses.

- Visual Inspection: Check for any signs of weaknesses, such as cracks or loose connections.

- Safety Checks: Ensure that all safety standards and regulations are met.

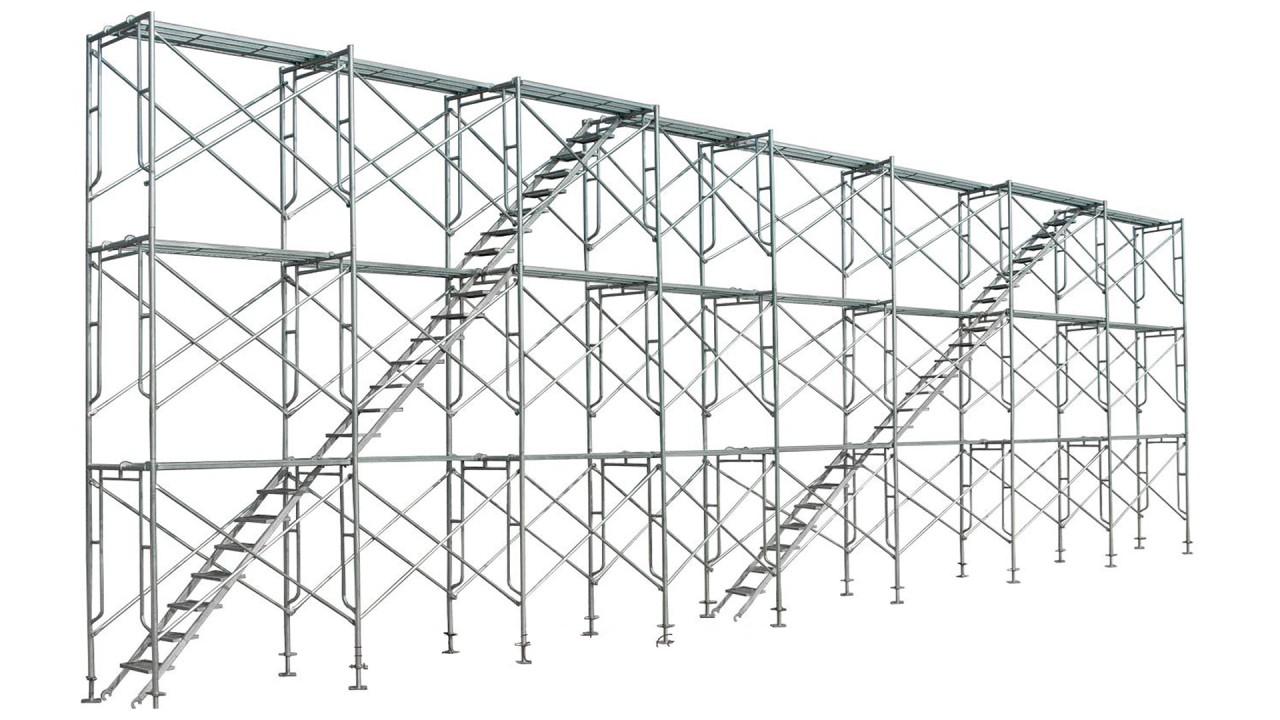

7. Integrating the H Frame into Your Project

Once the H frame is constructed and tested, integrate it into your project:

- Position the Frame: Place the H frame in its intended location and secure it according to your project’s requirements.

- Connect Other Components: Attach any additional elements or structures to the H frame as needed.

- Final Adjustments: Make any necessary adjustments to ensure proper fit and function.

8. Maintenance and Inspection

Regular maintenance and inspection are vital to ensure the continued safety and effectiveness of the H frame:

- Routine Checks: Periodically inspect the H frame for signs of wear or damage.

- Repairs: Address any issues promptly to prevent potential failures.

- Documentation: Keep records of inspections, repairs, and any modifications made.

9. Safety Considerations

Always prioritize safety when working with H frames:

- Personal Protective Equipment (PPE): Wear appropriate PPE, such as gloves, safety glasses, and helmets.

- Follow Standards: Adhere to relevant safety standards and guidelines for construction and engineering.

- Training: Ensure that all personnel involved in constructing or working with H frames are properly trained.

10. Conclusion

Implementing H frames in your projects involves careful planning, precise construction, and ongoing maintenance. By following this step-by-step guide, you can effectively incorporate H frames into your projects, ensuring stability, support, and success. Remember to adapt the guidelines to fit the specific requirements of your project and always prioritize safety.

By adhering to these steps, you’ll be well on your way to effectively using H frames in your projects, enhancing both their structural integrity and overall functionality.

Leave a Reply