Choosing the Right Pipe and Coupler Materials for Long-Term Durability

Selecting the right materials for pipes and couplers is crucial for ensuring the longevity and performance of any piping system. Proper choice of materials can prevent leaks, minimize maintenance, and avoid costly repairs. This article delves into the factors influencing material selection, the characteristics of various materials, and tips for choosing the best options for long-term durability.

Key Factors Influencing Material Selection

- Application and Environment:

- Pressure and Temperature: Pipes and couplers must withstand the pressures and temperatures of the system they are part of. For high-pressure or high-temperature environments, materials like stainless steel or reinforced plastic may be required.

- Chemical Exposure: Materials should be resistant to chemicals present in the environment or conveyed through the pipes. For example, PVC is resistant to many chemicals but not suitable for high temperatures or strong acids.

- Mechanical Properties:

- Strength and Flexibility: The chosen material should have adequate strength to handle the mechanical stresses and impacts. Additionally, flexibility is important in applications where pipes are subject to vibrations or ground movement.

- Corrosion Resistance: Corrosion can significantly reduce the lifespan of pipes and couplers. Materials like stainless steel or plastic are often chosen for their resistance to corrosion.

- Cost Considerations:

- Initial Cost vs. Lifetime Cost: While materials like copper or stainless steel might have a higher initial cost, their longevity and reduced maintenance can result in lower lifetime costs compared to cheaper alternatives.

- Installation and Maintenance:

- Ease of Installation: Some materials are easier to install than others, which can affect labor costs and installation time.

- Maintenance Requirements: Materials that are resistant to fouling, scaling, or other issues can reduce maintenance needs and prolong the system’s service life.

Common Pipe and Coupler Materials

- PVC (Polyvinyl Chloride):

- Characteristics: PVC is a popular choice for its cost-effectiveness and ease of installation. It is resistant to chemicals, making it suitable for a variety of applications, including plumbing and irrigation.

- Durability: PVC is not ideal for high temperatures or high-pressure environments. Over time, it can become brittle, especially under UV exposure.

- CPVC (Chlorinated Polyvinyl Chloride):

- Characteristics: CPVC is similar to PVC but with enhanced temperature and pressure resistance. It is often used in hot water applications.

- Durability: CPVC offers better thermal resistance than PVC but can still become brittle over time. It also requires proper handling to avoid damage during installation.

- PEX (Cross-Linked Polyethylene):

- Characteristics: PEX is flexible and resistant to freeze damage, making it a popular choice for residential plumbing. It is also resistant to scale and chlorine.

- Durability: PEX has good resistance to temperature fluctuations and pressure variations but may degrade with prolonged exposure to UV light.

- Copper:

- Characteristics: Copper pipes are durable, with excellent thermal conductivity and resistance to corrosion. They are often used in water supply lines.

- Durability: Copper is long-lasting but can be prone to corrosion if the water is acidic or if it is exposed to certain chemicals. It is also more expensive than plastic alternatives.

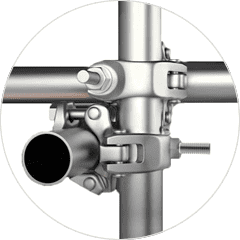

- Stainless Steel:

- Characteristics: Stainless steel pipes are highly resistant to corrosion and can handle high pressures and temperatures. They are often used in industrial applications.

- Durability: Stainless steel has a long service life and maintains its strength and integrity under harsh conditions, though it is one of the more expensive options.

- Ductile Iron:

- Characteristics: Ductile iron pipes are known for their strength and resistance to impact and pressure. They are commonly used in municipal water systems.

- Durability: Ductile iron is very durable and resistant to internal pressure but may require coating or lining to protect against corrosion, especially in aggressive soil conditions.

Tips for Choosing the Right Materials

- Assess System Requirements:

- Carefully evaluate the operational conditions of your piping system, including pressure, temperature, and chemical exposure. Select materials that meet or exceed these requirements.

- Consider Longevity and Maintenance:

- Opt for materials that offer a good balance between initial cost and long-term durability. Materials with lower maintenance needs can save time and money over the life of the system.

- Check Compatibility:

- Ensure that the pipe and coupler materials are compatible with each other and with any existing system components. Incompatibilities can lead to leaks or system failures.

- Review Local Codes and Standards:

- Verify that the materials comply with local building codes and industry standards. This ensures safety, legality, and compatibility with other systems.

- Consult with Experts:

- When in doubt, seek advice from professionals or engineers who can provide recommendations based on your specific application and requirements.

Conclusion

Choosing the right pipe and coupler materials is essential for ensuring the long-term durability and reliability of a piping system. By considering factors such as application conditions, mechanical properties, cost, and ease of maintenance, you can make informed decisions that will benefit your system for years to come. Evaluating the strengths and limitations of various materials, and consulting with experts as needed, will help you achieve optimal performance and longevity in your piping infrastructure.

Leave a Reply