“Top 7 Types of Scaffolding Couplers: A Complete Guide”

Top 7 Types of Scaffolding Couplers: A Complete Guide Scaffolding is a vital part of construction and maintenance projects, providing a temporary platform for workers and materials. Among its essential components are scaffolding couplers, which connect and secure scaffold tubes to form a strong, stable structure. Choosing the right type of coupler can significantly…

Expert Guide to Choosing the Best Floor Board Formwork Accessories

When it comes to construction projects, choosing the right floor board formwork accessories is critical for ensuring structural integrity, safety, and efficiency. Formwork accessories play a vital role in supporting and shaping the concrete until it hardens to the desired strength. With so many options available in the market, selecting the right accessories can…

The Complete Guide to Beam Floor Materials and Construction Techniques

The Complete Guide to Beam Floor Materials and Construction Techniques Beam floors are integral to creating sturdy and long-lasting structures. They provide a robust framework that supports both the flooring and the loads imposed on it. In this guide, we’ll explore the types of materials used in beam floors and the construction techniques that…

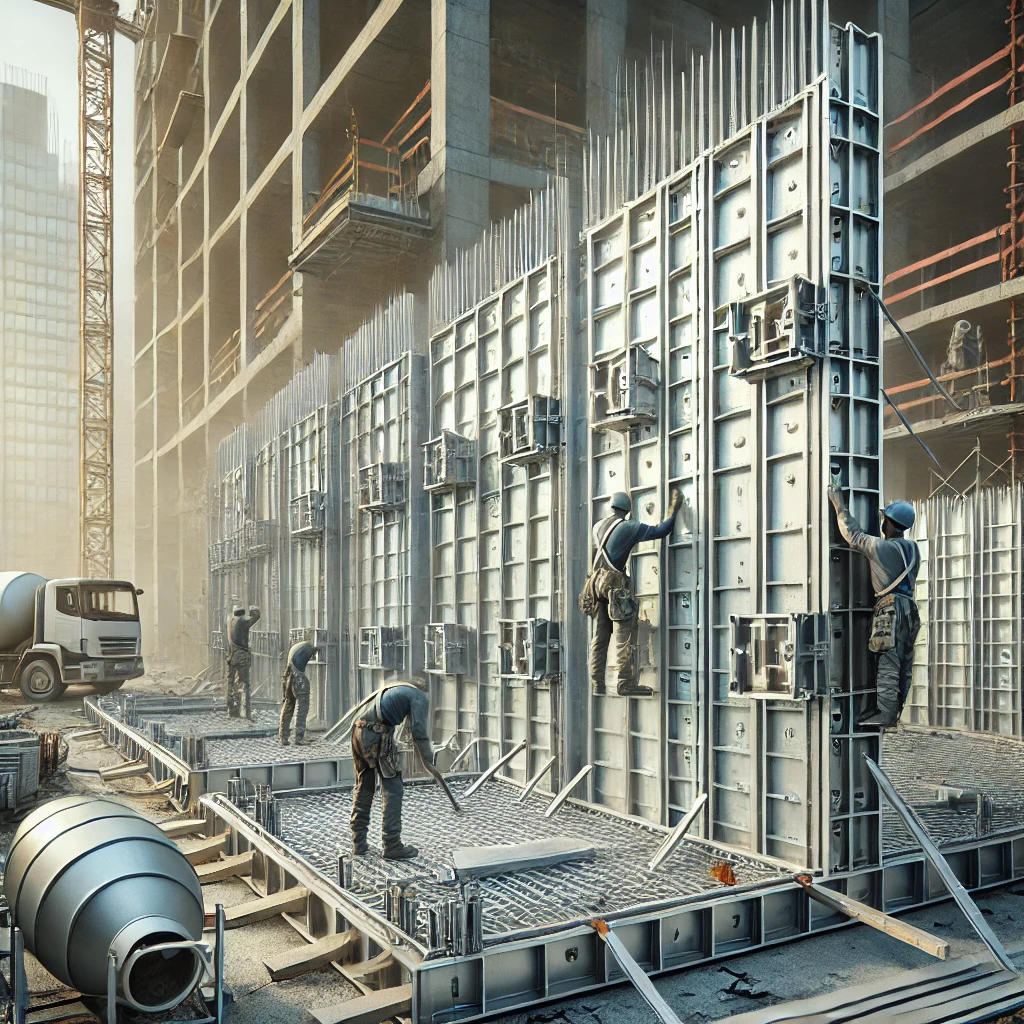

“Wall Panel Aluminum Formwork: Best Practices for Optimal Results”

Wall Panel Aluminum Formwork: Best Practices for Optimal Results Wall panel aluminum formwork has become a cornerstone of modern construction, offering unmatched precision, durability, and efficiency. It enables builders to create consistent, high-quality concrete walls with speed and cost-effectiveness. To maximize its benefits, following best practices for its design, assembly, usage, and maintenance is…

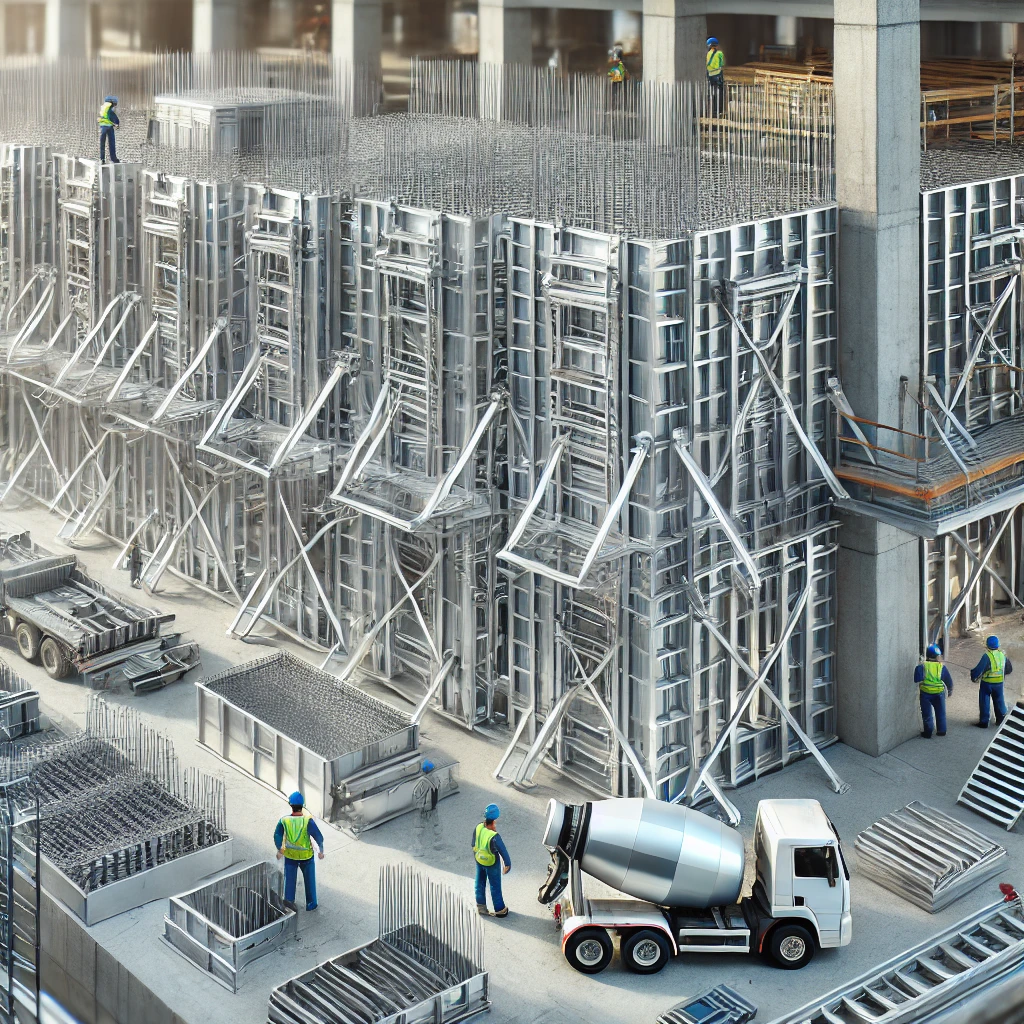

“”Expert Tips For Using Aluminum Formwork In Wall Corner Construction””

Wall corner Construction are a critical part of any structure, and aluminum formwork has emerged as one of the most efficient and precise systems for constructing them. If you’re planning to utilize aluminum formwork for wall corners, this guide will walk you through expert tips to ensure a smooth and successful construction process. Why…

“Your Ultimate Guide to Choosing the Best Scaffold Couplers”

Your Ultimate Guide to Choosing the Best Formwork Tube Scaffold Coupler In the world of construction, formwork tube scaffold couplers play an essential role in assembling secure, reliable scaffolding systems for concrete pouring. These couplers are the backbone of formwork scaffolding, ensuring stability, safety, and efficient project execution. This guide will take you through…

How to Maintain and Reuse Shuttering Planks for Long-Term Savings

How to Maintain and Reuse Shuttering Planks for Long-Term Savings Shuttering planks play a vital role in construction projects, acting as temporary molds to hold concrete in place until it sets. Proper maintenance and reuse of these planks not only save money but also contribute to sustainable construction practices. In this article, we’ll discuss…

“The Ultimate Guide to Choosing the Right Scaffold Planks”

The Ultimate Guide to Choosing the Right Scaffold Planks Introduction Scaffold planks are essential for creating stable platforms for workers at height. The right choice ensures safety, durability, and compliance with safety standards. This guide will help you select the best scaffold planks for your needs. 1. What Are Scaffold Planks? Scaffold planks are…

“Everything You Need to Know About Diagonal Braces in Structural Engineering”

Everything You Need to Know About Diagonal Braces in Structural Engineering In structural engineering, play a pivotal role in ensuring the strength, stability, and durability of various constructions. From skyscrapers to bridges, diagonal braces are a fundamental component in modern structural designs. In this comprehensive guide, we’ll dive deep into what diagonal braces are,…

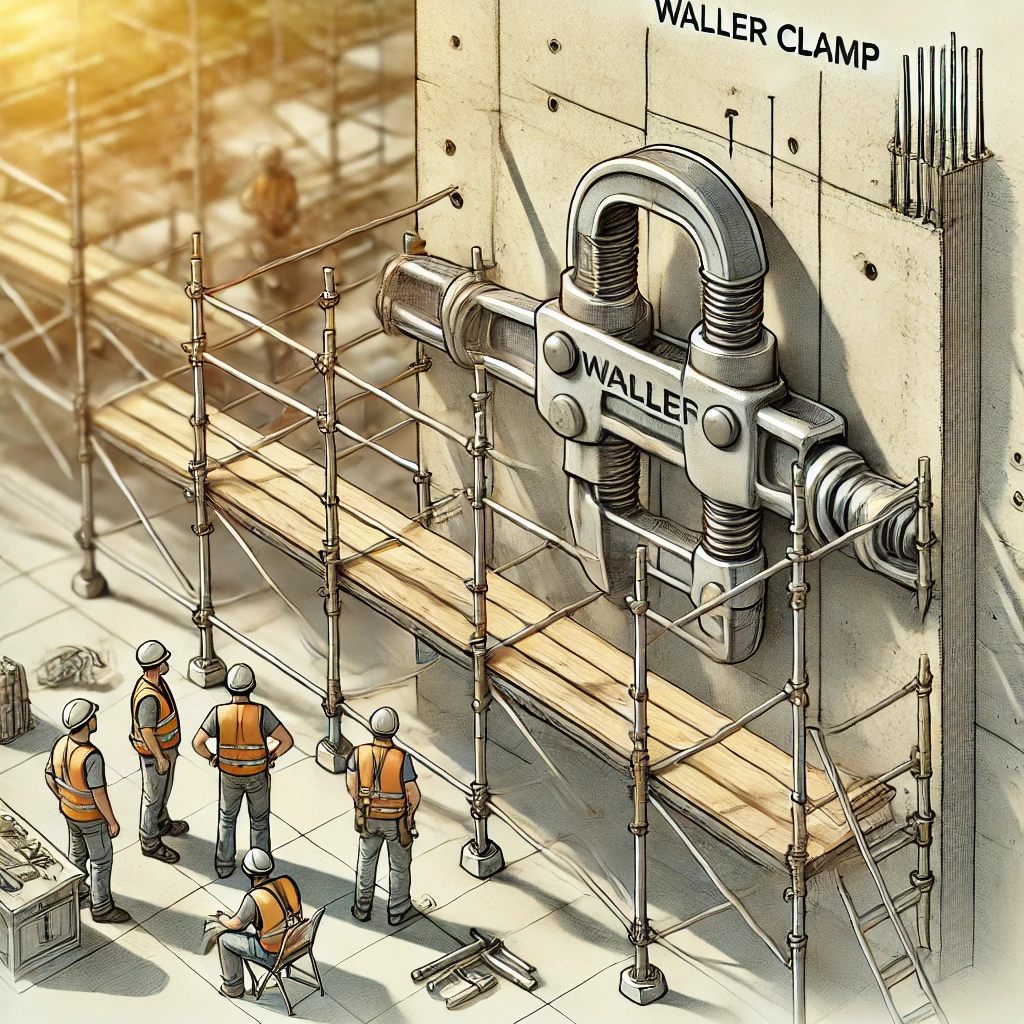

Waller Clamps for Scaffolding: Everything You Need to Know

Waller Clamps for Scaffolding: Everything You Need to Know Scaffolding is an essential component of modern construction projects, providing a stable and safe platform for workers to perform tasks at elevated heights. One of the critical tools used to enhance scaffolding stability is the waller clamp. In this article, we’ll explore waller clamps in…