Best Ringlock Horizontal System for Easy Assembly and Safety

Best Ringlock Horizontal System for Easy Assembly and Safety When it comes to construction scaffolding, safety and efficiency are top priorities. The Ringlock Horizontal System has emerged as one of the best choices for builders, offering a combination of ease of assembly, superior strength, and unmatched safety. In this blog, we’ll dive into the…

Ringlock Vertical for Sale – Best Prices & Superior Quality

Introduction When it comes to scaffolding, Ringlock Vertical systems are the backbone of any safe and efficient structure. Whether you’re working on high-rise buildings, bridges, or industrial projects, choosing a high-quality Ringlock Vertical is crucial for durability and worker safety. If you’re looking for Ringlock Vertical for sale at the best prices without compromising…

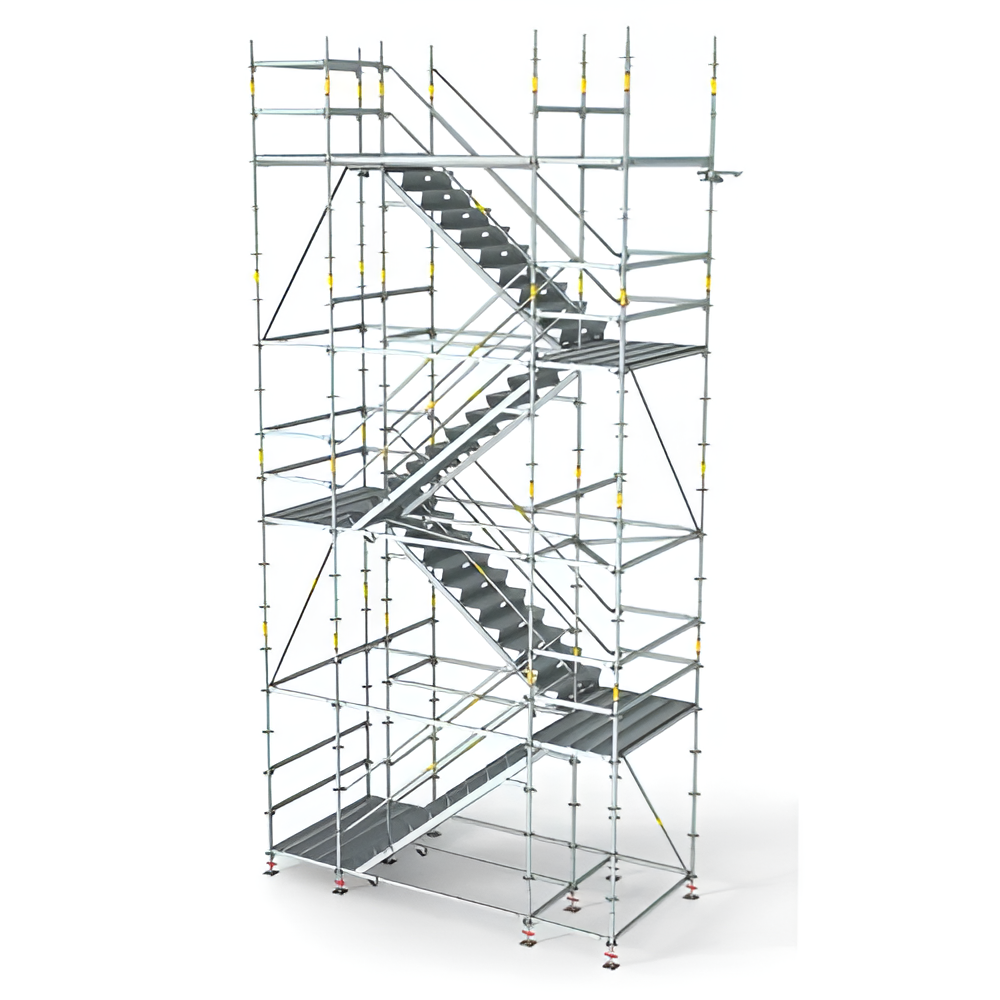

Enhance Site Safety with MS Cuplock Staircase Handrail – Shop Now

Introduction In construction and industrial worksites, safety is a top priority. A well-structured scaffolding system ensures a secure working environment for laborers, preventing accidents and injuries. One essential component of scaffolding is the MS Cuplock Staircase Handrail, which provides stability and support for workers moving up and down the structure. If you’re looking for…

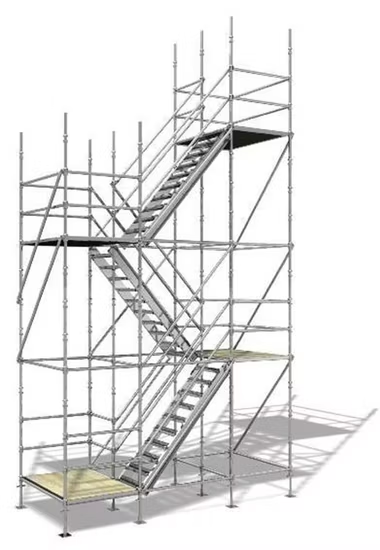

Find the Best MS Cuplock Staircase – Durable, Strong & Cost-Effective

The MS Cuplock Staircase is an essential scaffolding component that ensures safe and efficient access to different levels on construction sites, industrial projects, and maintenance work. Designed for durability, strength, and cost-effectiveness, it has become a preferred choice for contractors and engineers worldwide. In this article, we will explore the features, benefits, applications, and…

“”Scaffolding Made Easy: Understanding Cuplock Cantilever Brackets””

Scaffolding Made Easy: Understanding Cuplock Cantilever Brackets Scaffolding is an essential component in construction and industrial projects, providing a safe and efficient platform for workers at elevated heights. One critical element that enhances the versatility of scaffolding systems is the Cuplock Cantilever Bracket. This blog explores what Cuplock Cantilever Brackets are, their features, benefits,…

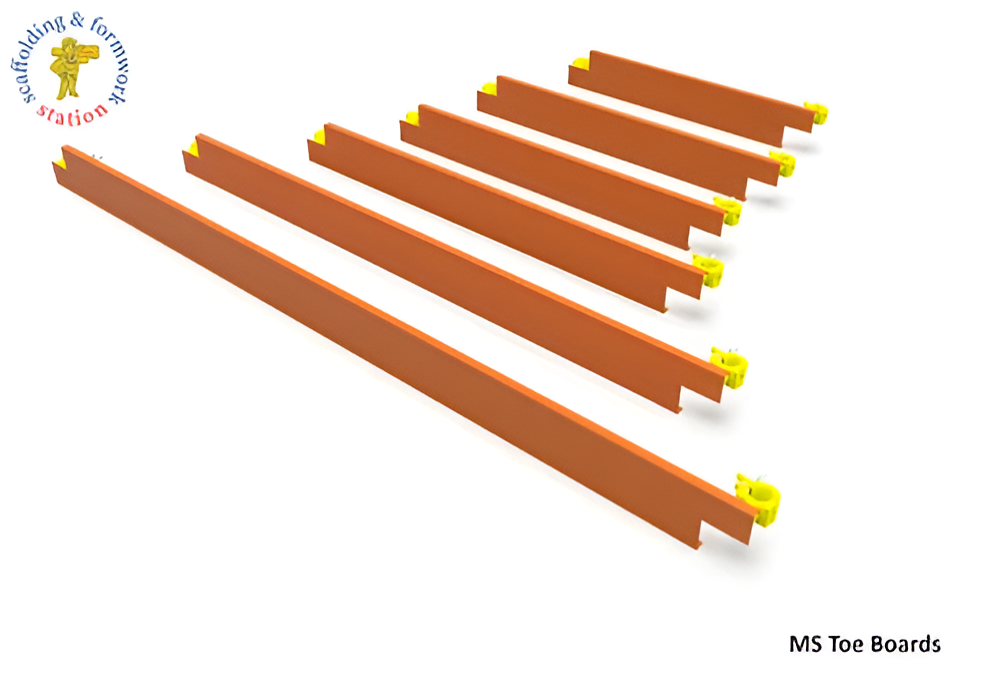

MS Cuplock Toe Board Suppliers – Get the Best Deals Today

MS Cuplock Toe Board Suppliers – Get the Best Deals Today The construction industry relies heavily on scaffolding systems to ensure safety, efficiency, and flexibility during building projects. Among the essential components of a scaffolding system is the MS Cuplock Toe Board, which plays a critical role in providing edge protection and preventing tools…

“What Is a Cuplock Spigot? Everything You Need to Know”

What Is a Cuplock Spigot? Everything You Need to Know When it comes to scaffolding systems, durability, ease of use, and efficiency are key factors in determining the best solution for construction projects. Among the various scaffolding systems, the cuplock spigot system stands out for its versatility and reliability. In this article, we’ll dive…

“”Cuplock Ledger Scaffolding: Safe, Secure, And Easy To Assemble””

Cuplock Ledger Scaffolding: Safe, Secure, and Easy to Assemble When it comes to construction projects, safety, efficiency, and durability are essential. One system that has revolutionized the scaffolding industry is Cuplock Ledger Scaffolding. Designed to provide robust support and flexibility, it has become the go-to choice for contractors and builders worldwide. In this blog,…

Cuplock Vertical Scaffolding vs. Other Systems: Which is Better?

Here’s a detailed blog on “Cuplock Vertical Scaffolding vs. Other Systems: Which is Better?” with suggested image placements. Cuplock Vertical Scaffolding vs. Other Systems: Which is Better? IntroductionScaffolding plays a crucial role in construction projects, providing a safe platform for workers and materials. Among the many scaffolding systems available, cuplock vertical scaffolding stands out…

“How to Choose the Right Formwork Props for Your Construction Project”

How to Choose the Right Formwork Props for Your Construction Project Formwork props are a critical component in construction projects, ensuring the stability and safety of temporary structures during concrete pouring and curing. Choosing the right props can save time, reduce costs, and enhance safety on-site. Here’s a detailed guide to help you make…