When it comes to modern construction techniques, aluminum formwork has become a popular choice for building strong, durable structures efficiently. A key component in the aluminum formwork system is the use of props. These essential elements play a vital role in ensuring the stability, safety, and overall success of construction projects. Let’s dive into why aluminum formwork props are indispensable in the construction process.

1. Providing Structural Support

One of the most important functions of props in aluminum formwork is to provide critical vertical support to the entire formwork structure. During the concrete pouring and setting phase, props bear the load of the formwork and ensure that it remains securely in place. Without proper support, the formwork could collapse, leading to costly delays and potential safety risks.

2. Ensuring Load Distribution

The weight of wet concrete can be significant. Aluminum formwork props help evenly distribute this load across the structure, preventing overloading in certain areas. This even distribution of weight ensures that the formwork system doesn’t buckle or distort, maintaining its integrity during the curing process.

3. Enhancing Safety

Safety is a top priority in construction, and props are a critical element in maintaining a safe working environment. Properly positioned props reduce the risk of accidents caused by unstable formwork. Their use ensures that the formwork structure remains firm and steady, offering safety to the workers on site.

4. Adjustable for Flexibility

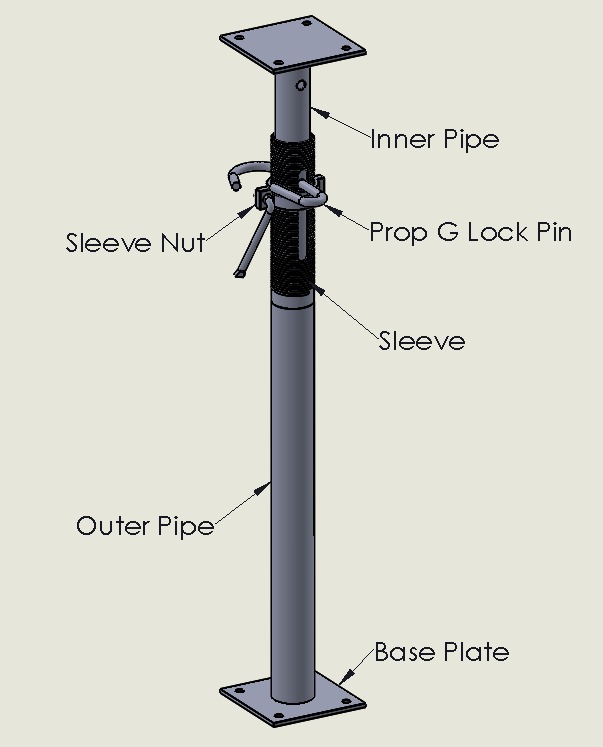

Aluminum formwork props are adjustable, allowing for easy modification to accommodate different construction requirements. Whether you need to adjust for different heights or angles, props can be easily repositioned to ensure that the formwork is perfectly aligned. This flexibility helps construction teams save time and adapt to varying project needs.

5. Reusability and Cost Efficiency

Aluminum formwork props are built to last. Their durability and reusability make them an excellent investment for construction companies. Since props can be used multiple times across different projects, they significantly reduce material costs in the long term. This reusability makes aluminum formwork systems a cost-effective choice for both small and large-scale projects.

6. Supporting Fast and Efficient Construction

Aluminum formwork systems are designed for quick installation and removal, and props play a crucial role in this. Since props are easy to adjust and install, construction teams can set up and dismantle formwork faster, leading to shorter project timelines. This efficiency is especially important for projects that need to be completed on tight schedules.

7. Maintaining Formwork Alignment

During the concrete pouring and curing process, it’s crucial that the formwork stays aligned to achieve the desired shape and finish. Props help in leveling and maintaining proper alignment throughout the process. This ensures the structure’s design is accurately followed, resulting in higher-quality construction.

Conclusion

In summary, aluminum formwork props are essential for ensuring the success of construction projects. They provide support, safety, and efficiency while also being cost-effective and adjustable. By distributing the load evenly and stabilizing the formwork structure, props contribute to creating high-quality and durable buildings. If you’re looking to streamline your construction process and improve safety standards, investing in aluminum formwork and proper prop usage is a smart move for any project.

Leave a Reply