Aluminium formwork has gained significant popularity in modern construction due to its durability, cost-effectiveness, and ability to improve the speed of construction. Used primarily for creating concrete structures, it provides a reliable and efficient way to form walls, slabs, and columns. In this blog, we will dive deep into the technical specifications of aluminium formwork and why it should be considered for your next construction project.

What is Aluminium Formwork?

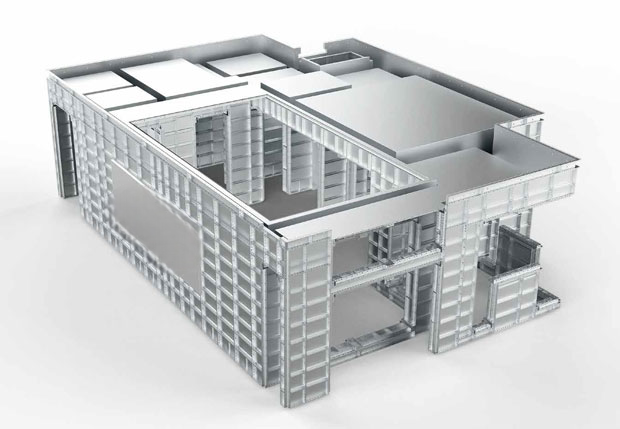

Aluminium formwork is a system made of high-quality aluminum components that are used to shape and support concrete until it hardens. The formwork is reusable, lightweight, and is designed to provide precise and high-quality finishes on concrete structures. It is commonly used in the construction of residential buildings, commercial projects, and infrastructure works, where speed and quality are essential.

Key Technical Specifications of Aluminium Formwork

- Material Composition

- Aluminium formwork is typically made from high-strength aluminum alloy. This provides an optimal balance of strength, weight, and durability. Unlike traditional timber formwork, which can weaken over time, aluminium formwork retains its strength and can be reused multiple times with minimal wear and tear.

- The alloy used in the construction of the panels is 6061-T6, which ensures a high resistance to corrosion, making it suitable for various environmental conditions.

- Weight and Ease of Handling

- One of the most significant advantages of aluminium formwork is its lightweight nature. Aluminium panels weigh significantly less than their steel counterparts, which makes handling, transport, and installation much easier.

- The light weight reduces the need for heavy lifting equipment and minimizes labor costs and time on site.

- Load-Bearing Capacity

- The load-bearing capacity of aluminium formwork is another critical factor to consider. The formwork system is designed to withstand the pressures of wet concrete during casting. It is engineered to bear substantial loads without deformation, ensuring that the concrete maintains its shape and strength.

- Depending on the thickness of the panels and the specific design, aluminium formwork can typically support concrete loads of up to 60 kN/m² or more.

- Panel Dimensions

- The panels are manufactured in various standard sizes, typically ranging from 3m to 6m in length and 1m to 1.2m in height, though custom dimensions can also be made. The flexibility in panel sizes makes it suitable for both large-scale projects and smaller, more intricate designs.

- Panels are designed to interlock, allowing for flexibility in the construction of different types of structures, from simple walls to complex slabs and beams.

- Reusability

- Reusability is one of the defining characteristics of aluminium formwork. Aluminium formwork systems can be used over 250 times with minimal deterioration, which is a significant improvement over traditional timber formwork that can only be used a few times before it needs to be replaced.

- This reusability results in a reduction in long-term costs and helps improve the sustainability of the construction process by reducing waste.

- Precision and Finish

- The precision and finish quality of aluminium formwork are excellent. The formwork panels are designed to create a smooth and precise surface finish on the concrete, reducing the need for post-construction finishing work.

- The exact dimensions and tight fit between panels help to achieve accurate tolerances, ensuring that the resulting concrete structure is strong and well-aligned.

- Thermal Conductivity and Insulation

- Aluminium has excellent thermal conductivity, which helps in the even curing of the concrete. However, its insulating properties ensure that the concrete structure doesn’t lose heat too quickly during the curing process, allowing for proper hardening and minimizing the risk of cracks due to rapid temperature changes.

- In regions with extreme temperatures, the formwork can help manage the temperature of the concrete, especially during hot or cold weather.

- Ease of Assembly and Disassembly

- Aluminium formwork systems are designed for quick and easy assembly and disassembly. The panels interlock and require minimal tools, reducing the overall time needed for setup.

- With the use of cranes, the panels can be positioned accurately, reducing labor costs and construction time.

- Compatibility with Other Formwork Systems

- Aluminium formwork systems can be used in combination with other formwork types, such as steel or plastic formwork, allowing for flexibility in various construction scenarios.

- For projects that require complex or non-standard shapes, the modular design of aluminium formwork systems can be adapted to meet unique requirements.

Advantages of Using Aluminium Formwork

- Cost-Effective

- While the initial cost of aluminium formwork might be higher than traditional timber or steel options, the long-term savings are significant. The reusability of the system reduces the need for constant purchases of new formwork materials, leading to a reduction in overall project costs.

- Time-Saving

- Aluminium formwork systems speed up the construction process, as they are quick to assemble and disassemble. This is particularly advantageous for projects with tight deadlines, as it helps reduce construction time and labor costs.

- Improved Safety

- The lightweight nature of aluminium formwork reduces the risks associated with lifting and handling heavy materials on site, which can improve worker safety.

- Environmental Sustainability

- Aluminium formwork is environmentally friendly, as it is highly recyclable and produces minimal waste compared to other materials like timber. Additionally, its long lifespan means fewer resources need to be used over time.

- Durable and Corrosion-Resistant

- Aluminium’s resistance to corrosion ensures that the formwork can withstand exposure to harsh weather conditions, including rain and humidity, making it ideal for a variety of climates.

Conclusion

Aluminium formwork is a game-changer for the construction industry, providing numerous benefits, including cost-efficiency, reusability, precision, and faster construction timelines. Understanding the technical specifications of aluminium formwork is essential for making informed decisions when selecting the right formwork system for your project. Whether you’re building a residential, commercial, or industrial structure, aluminium formwork’s advantages can help take your project to the next level while ensuring the highest standards of quality and safety.

If you’re planning your next construction project, considering the use of aluminium formwork could lead to significant long-term benefits in both cost and time savings. Choose wisely, and your project will be on its way to success!

Leave a Reply